We are pleased to offer you a freestanding, transportable processing unit for the disassembly, processing, and storage of the carcasses of hunted game. The processing room with cooling meets all essential veterinary standards, allowing it to be declared as a game reception facility.

The walls, ceiling, and floor are made of 100 mm-thick insulated polyurethane panels (manufacturer-approved). In addition to insulation, the floor is covered with acid-resistant sheet metal to improve cleaning and disinfection.

We place great emphasis on the quality of cooling. Therefore, the unit uses an Aspera compressor-based cooling system and a TECO fan cooler, ensuring the proper temperatures for chilling the game carcasses.

The electronic cooling control allows the desired temperature to be set within a flexible range, even down to freezing levels (we set the operating range from 0°C to -2°C). This ensures that the game carcasses can be stored successfully for several days (specific storage duration and temperature requirements may vary depending on veterinary regulations).

The container has a self-supporting structure, with canopies over the entrances and cooling units. Its dimensions allow for easy transportation and assembly of both parts while ensuring optimal use.

All doors are insulated (including those for the working area), so the cooling section can be successfully expanded even under extreme conditions.

Exterior colour and flooring options:

Colours: green (RAL 6005) or white (RAL 9010)

Flooring: smooth stainless steel, R13 aluminium checker plate, or self-levelling polyurethane resin flooring.

Equipment

-

CHIGO air conditioning with remote control

-

2 x cooling units

-

3 x acid-resistant stainless steel sinks

-

Butcher’s table with a compartment made of acid-resistant sheet metal, size: 200 x 90 cm

-

Removable plastic plate, size 200 x 40 cm

-

Acid-resistant sheet metal cladding on the wall of the dissection room, size 514 x 124 cm

-

Hanging shelf made of acid-resistant sheet metal, size 76 x 37 cm in the output buffer area

-

First-aid kit

-

Toilet

-

Electric rope winch with a load capacity of 600 kg above the entrance to the cooling room of the goods acceptance area

-

Electrical and lighting installation in cable channels in the cooling room

-

Electronic control for programming temperature settings from +10°C to -5°C

-

Electric control cabinets with overload protection modules – 2 pieces

-

A set of keys for both doors (2x)

-

Electronic energy meter

-

Rail for hanging hooks

-

A set of 5 hooks

-

230 V-AC

Specification

| Size [cm] | Length [L] | Width [S] | Height [H] |

| External dimensions | 600 | 480 | 295 |

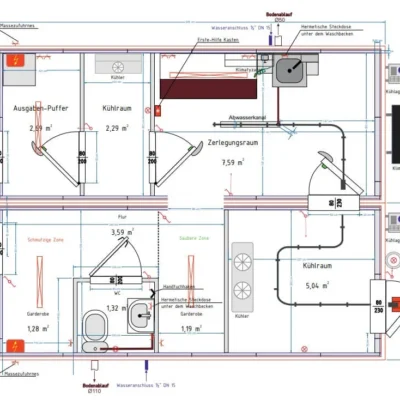

Clean zone:

Cooling room for raw material reception – 4.54 m²

Processing room – 7.26 m²

Cooling room – 2.16 m²

Output buffer – 2.59 m²

Clean changing room – 1.14 m²

Dirty zone:

Dirty changing room – 1.14 m²

Corridor – 3.99 m²

Toilet – 1.28 m²

The container has extended canopies over the entrances with lengths of 1.20 m and 0.50 m, respectively. The total length of the container with these canopies is 7700 mm.

The built-in cooling doors are 900 mm wide and are equipped with safety locks.

We deliver the units anywhere in the UK.

We provide a comprehensive 24-month warranty on all cooling containers, including a service during the warranty period. Additionally, we offer an optional post-warranty service with customer site visits for an additional fee.

Gallery

Copyrights 2025 H&H Cooling Systems