We are pleased to offer you a freestanding, transportable processing unit for the disassembly, processing, and storage of the carcasses of hunted game. The processing room with cooling meets all essential veterinary standards, allowing it to be declared as a game reception facility.

The walls, ceiling, and floor are made of 100 mm-thick insulated polyurethane panels (manufacturer-approved). In addition to insulation, the floor is covered with acid-resistant sheet metal to improve cleaning and disinfection.

We place great emphasis on the quality of cooling. Therefore, the unit uses an Aspera compressor-based cooling system and a TECO fan cooler, ensuring the proper temperatures for chilling the game carcasses.

The electronic cooling control allows the desired temperature to be set within a flexible range, even down to freezing levels (we set the operating range from 0°C to -2°C). This ensures that the game carcasses can be stored successfully for several days (specific storage duration and temperature requirements may vary depending on veterinary regulations).

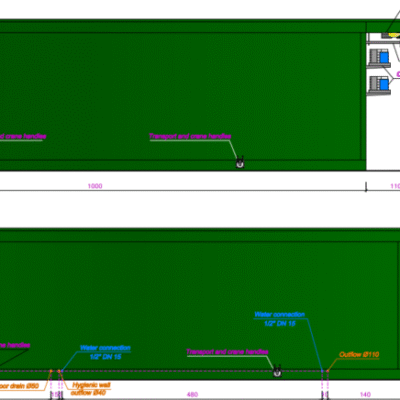

The container has a self-supporting structure, with canopies over the entrances and cooling units. Its dimensions allow for easy transportation and assembly of both parts while ensuring optimal use.

All doors are insulated (including those for the working area), so the cooling section can be successfully expanded even under extreme conditions.

Exterior colour and flooring options:

Colours: green (RAL 6005) or white (RAL 9010)

Flooring: smooth stainless steel, R13 aluminium checker plate, or self-levelling polyurethane resin flooring.

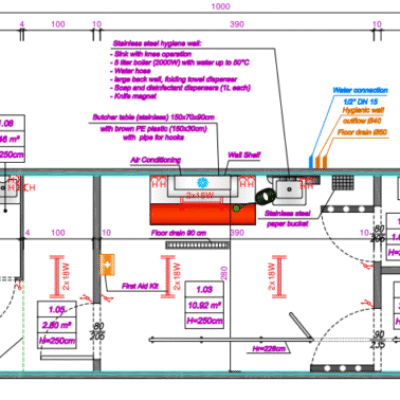

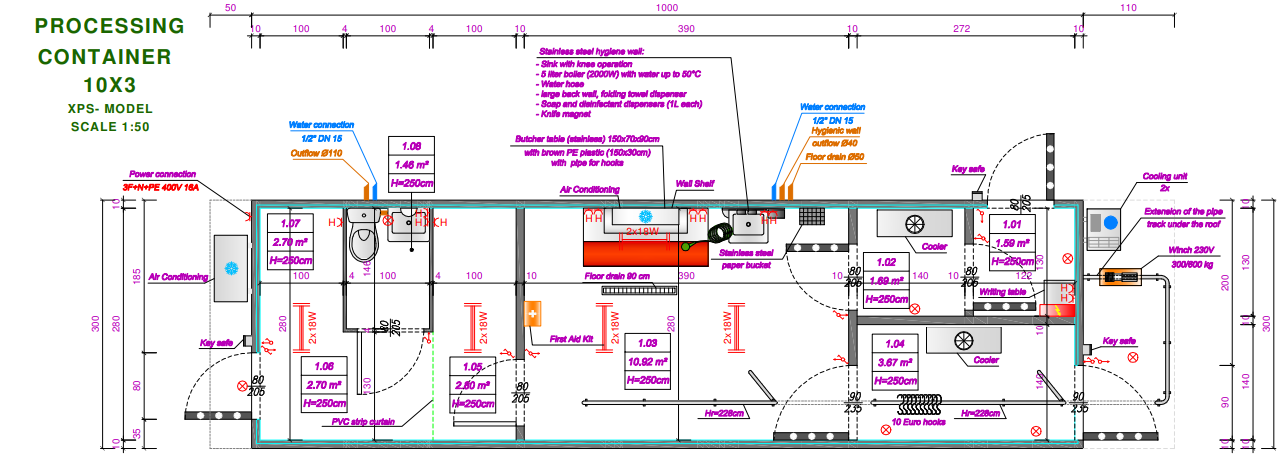

Equipment

Raw Material Reception Area

This is a cold storage room equipped with a rope hoist with a lifting capacity of 300 kg & 600 kg, as well as a rail system for hanging carcasses/raw material.

After reception, the carcass is transferred to the Cutting Room.

The Cutting Room is equipped with:

- A stainless steel cutting table measuring 150 x 70 x 90 cm, with a replaceable polyethylene (PE) tabletop measuring 150 x 30 cm

- A hygiene station fitted with a knee-operated sink, 5-litre water heater, soap and disinfectant dispensers, and a potable water hose

- A first aid kit

- A stainless steel shelf

- A Sinclair air conditioner with remote control

- A floor drain

From the Cutting Room, the finished products are transferred to the Cold Storage, and then to the Dispatch Buffer Zone.

Cold Storage – with temperature control ranging from +10 °C to -5 °C.

Dispatch Buffer Zone is a neutral room equipped with a writing desk.

The 10 x 3 metre processing container also includes an integrated staff area with a separate entrance.

The staff area is equipped with:

- Changing room – dirty zone

- Toilet

- Changing room – clean zone, from which there is direct access to the Cutting Room.

Specification

| Size | Length [L] | Width [S] | Height [H] |

| External dimensions | 1160 cm / 38ft | 300 cm / 9,8ft | 280 cm / 9,2ft |

We deliver the units anywhere in the UK.

We provide a comprehensive 24-month warranty on all cooling containers, including a service during the warranty period. Additionally, we offer an optional post-warranty service with customer site visits for an additional fee.

Gallery

Copyrights 2025 H&H Cooling Systems